Each material used in making our products is carefully selected by our experts to ensure it’s top-quality.

At Aromaticstore, for candle and diffuser production, we only use:

Premium quality can only be born by combining skilled work with the best materials available.

Each material used in making our products is carefully selected by our experts to ensure it’s top-quality.

At Aromaticstore, for candle and diffuser production, we only use:

All materials will go through strict in-house inspections. Only qualified material will be put into mass production.

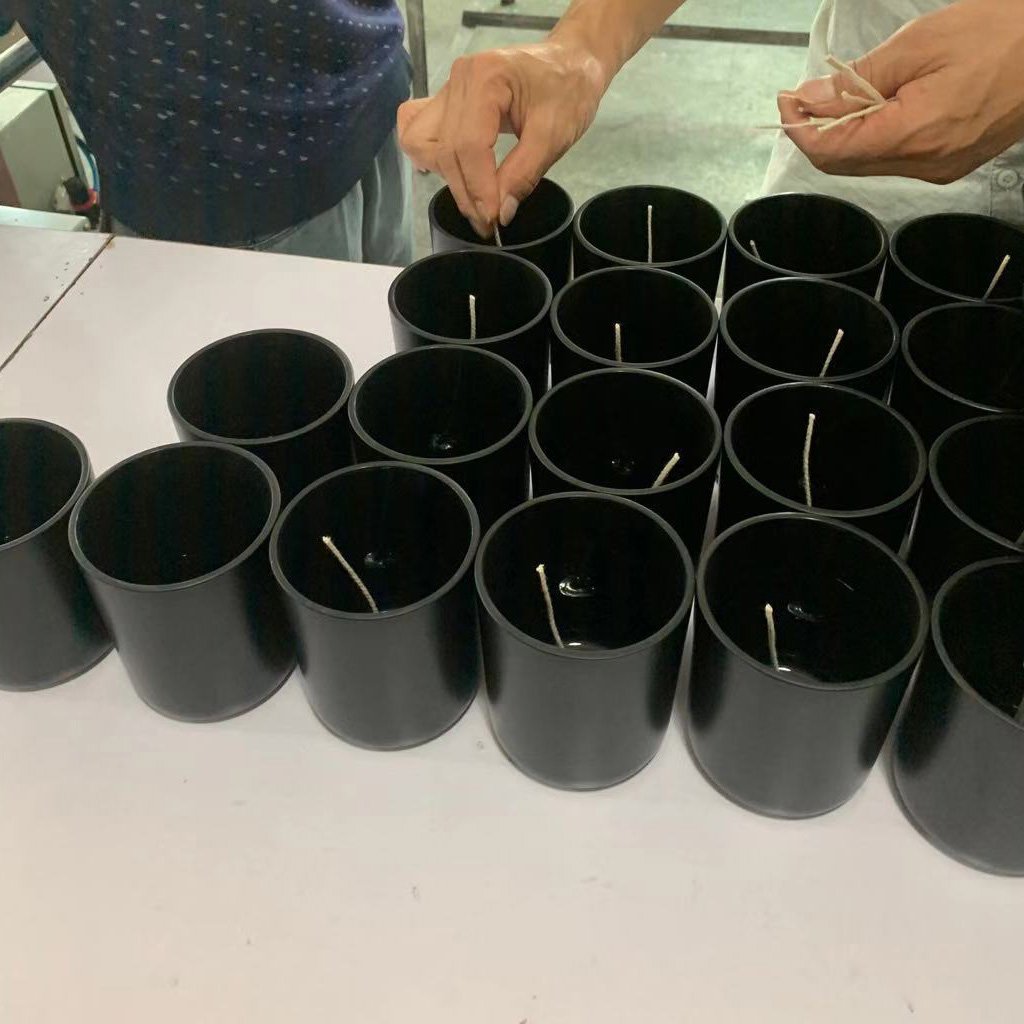

Before filling ,the empty container will cleaning the dust and paper scraps.

Set the container and fix the wick into the center of the container.

Fill liquid ,after half solidify ,adjust the wick and fill last 10mm wax face.

After Wax filled , every products is cleaned thoroughly to remove any wax & handprint for an eye-pleasing & elegant look. then labeling

put the products into carton

loading into container

Measure the Container to make sure the size is correct.

The candle surface must have no bubbles, cracks, chips or damage

Measure the distance from wax face to container top to make sure the size is consistent among in the same batch.

smell it and compare with samples is consistent .

The candle must have a bright, even flame; the flame should not jump. Any burning time of the candle listed on the product package must be reached. If this time is <=4 hours, check that the burning time is matched. If the candles listed burn time is more than 4 hours, split the candle into two equal halves, and perform the burning test on both halves of the candle, afterward recording the total burn time.

Check the position of the wick (During the burning the wick’s end should bend evenly up to the outer edge of the flame), measure the height of the flame in mm and check the odor of the smoke and candle – The flame should burn without a visible release of smoke. Put the paper up to the flame and check whether there is any black smoke. Also check that the candle does not drip (slight wax run-off is tolerable for candles <= 30 mm diameter).

Blow out the candle. After blowing out the candle, the tip of the wick will always continue to glow for some time but it must not relight into a full flame. For a candle <=30 mm diameter, the wick should only continue to glow for no more than 15 seconds. For a candle over 30 mm diameter, the wick should only continue to glow for no more than 20 seconds.

Check the wick to make sure the size is correct. The wick must be placed in the center.

Split the candle in half to check the wick: 1.The wick should be centered and run through the whole candle. 2. The candle should not contain a second wick (exception: candles with more than one wick due to the design).

Measure to see if the paper is as thick as required .

Check if the Color and printing is consistent with the pantone or samples .

Carefully inspect the surface to see if there are any scratches & stains,Perform a rub test and an adhesive test for all printing, markings and logos.

Measure the Label to make sure the position is as customer required.

Check if the Color and printing is consistent with the pantone or samples .

At Aromaticstore, we place great importance on the quality of the service we give to our clients. We are certified against ISO 22716 :2007(E) for the provision of design, development, manufacture, packaging and repackaging services of candles and reed diffuser products to meet own label and client specifications. Plus packing and repackaging of customer supplied cosmetic products. This certification helps us in exceeding customer expectations and delivering excellent customer service. Quality is nature to us; we produce all our candles on site where they are poured to the highest quality standards and delivered on time to the customer. Quality checks are performed during production and packing to ensure the rigorous attention to detail is maintained throughout.

We are fully certified for Guideline for Good Manufacture Practice of Cosmetic Products,Ensure product safety; improve product quality; Eliminate dangerous accidents; Reduce the risk of injury or death to consumers from the product; Reduce the risk of public recall of products; Comply with regulations and trade guidelines good working environment; Effective cost control and international recognition; Enhance product competitiveness; Effective product traceability;

Shanghai aromaticstore use the Sedex platform to track our supply chain and support our sustainable procurement goals. Sedex is the world’s largest data platform for supply chain assessment, to store, analyse, share and report on sustainability practices. Allowing Customer to gain visibility of working conditions and environmental performance in our supply chain.

C316A, No.1111, JinDu Road, Min Hang District, Shanghai,201108, China.

info@aromaticstore.com

+86 13795292602